Crown Battery

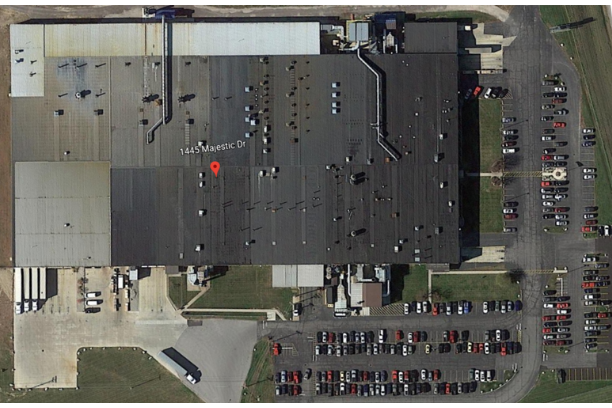

In 1962, William J Koenig, a German immigrant pursuing the American dream, opened the doors to a small battery repair shop in Fremont, OH.

More than 85 years of experience with lead-acid batteries, chargers, and related accessory products have made Crown Battery a leader in the global battery industry.

-

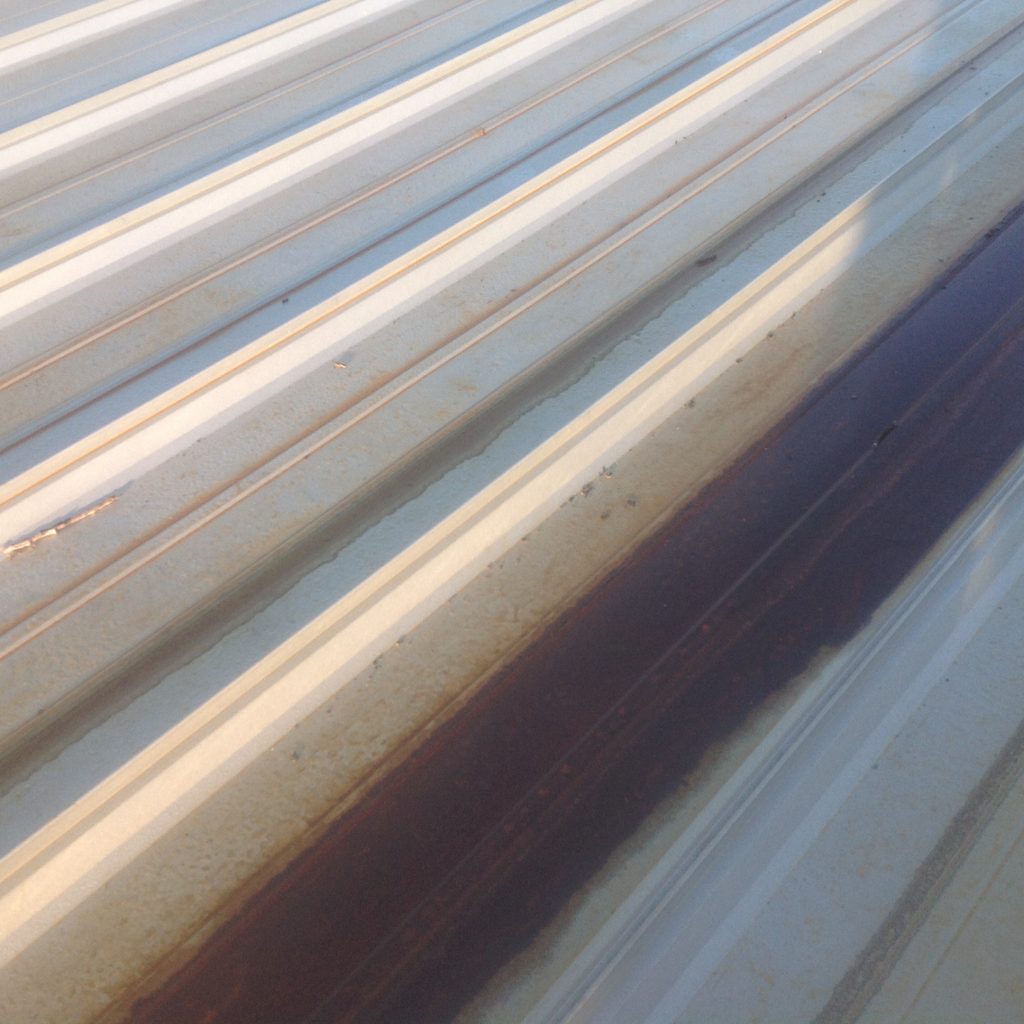

- Multiple sections of the metal roof were extremely corroded and rotted through.

-

- The metal roof's Internal gutters had rotted through.

-

- Condensation was continuously reactivating chemical vapors, which was causing fast-forming rust.

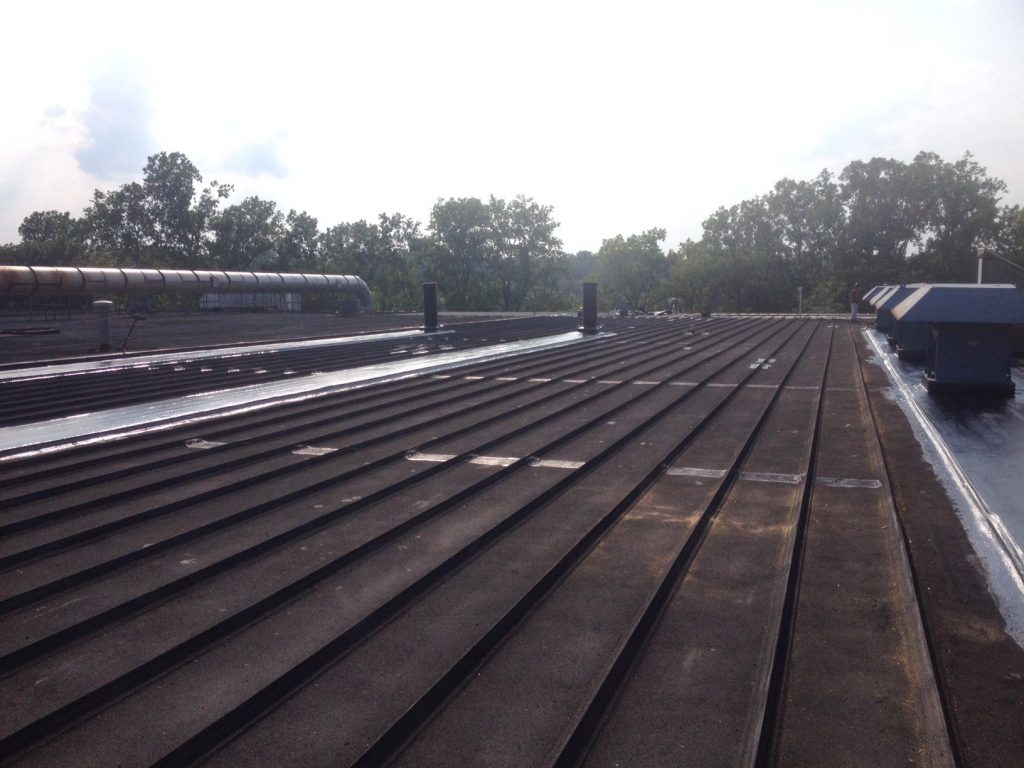

Located in northern Ohio, the Crown Battery facility sees high winds and sufficient precipitation throughout the year. That means any crack in metal roof panels, exposed seams, or punctures from fasteners were collecting moisture all year long.

Northeastern weather patterns aside, what was taking place under the metal roof, was also a contributing factor to the accelerated degradation rate.

The production of lead-acid batteries is corrosive by nature and subjects any facility roof to a combination of dangerous chemicals and heat treatments.

Industrial metal roofs usually have very specific points in their building where the roof system is degrading faster than the rest of it.

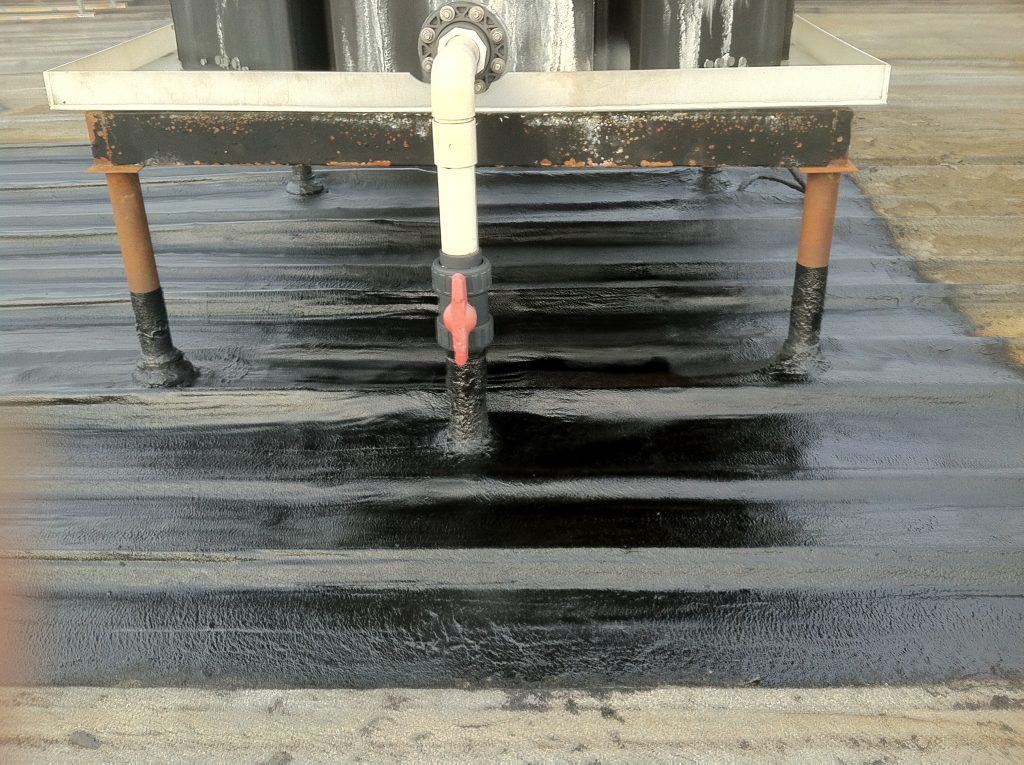

A concentrated area under the metal roof, with typical off-gassing due to battery production inside the facility.

Accelerated metal roof degradation stems from manufacturing processes, high heat, and off-gassing underneath the panels.

These visible vulnerable points of metal degradation on top of the metal roof are almost always directly above areas of concentrated heat, and chemical off-gassing that occur underneath, on the production floor.

When one area of the metal roof gets damaged, maintenance managers have to move whatever equipment is directly underneath to a new area within the facility to avoid moisture. And the same process will happen again and again.

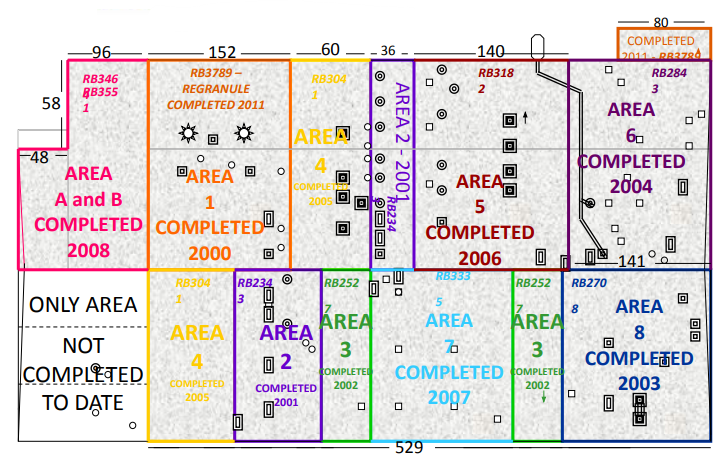

Thermal-Tec Roofing is proud to have worked with Crown Battery for more than 15 years – Helping them restore their facility's metal roof, section by section.

Sealing vulnerable areas with asphalt

Replacing metal on damaged areas

Applying MR Multi-Ply Solution

Application of Granules