Roofing Solutions for Industrial Chemical Facilities

Keeping your facility watertight is important for all chemical companies. Chemical plants and refineries have extremely dangerous environments to work in. Facilities undergo strict annual inspections covering not only the building itself but also the handling and disposal of by-products. Accordingly, equipment integrity and safety are paramount because the consequences can be deadly.

Human error accounts for a sizable portion of work-related accidents in any industry. There’s no way of getting around that. What we can get around and address - are other areas that can cause accidents. Generally, this practice includes proper maintenance and upkeep of materials and equipment. You don't want a compromised roof at a chemical plant.

You don't want a compromised roof at a chemical plant.

Chemical Plant Roof Restoration Prevents Accidents

Poorly kept equipment and/or material can not only produce faulty products but can also lead to accidents. That’s why you have all the safety protocols and procedures in place, to minimize the possibility of human error. That being said, have you ever considered your facility’s roof as a piece of essential equipment? It’s the most important piece of equipment in the entire building.

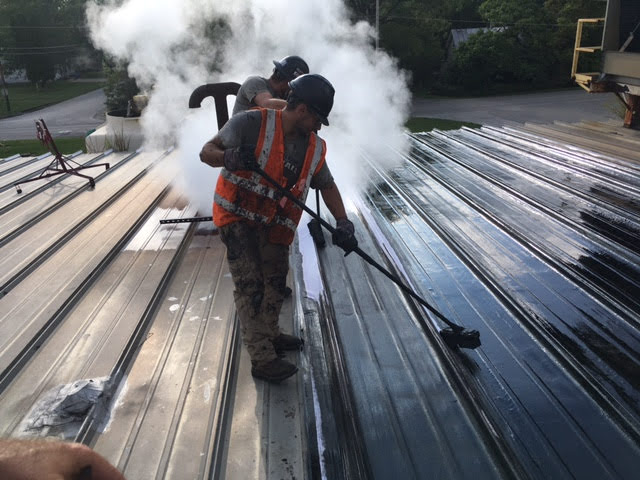

Don’t Risk Any Downtime – Let Professionals Secure Your Roof

Thermal-Tec’s MR Multi-Ply® Roof System is one of the few in the industry that can stand up to high-intensity, mission-critical environments in chemical plants. Our asphalt-based layers are resistant to corrosion, heat, and chemical degradation. This makes our roofing system essential to not only chemical facilities but any industry with a corrosive environment.