The Top-Down Approach to Commercial & Industrial Roofing

Why Thermal-Tec does things differently for heavy-industrial and commercial clients

In the world of commercial and industrial roofing, many contractors talk about process. At Thermal-Tec Roofing, we believe the real differentiator is culture. Our Top-Down Approach to commercial and industrial roofing isn't just another procedural checklist. It's who we are. A cultural norm stamped and molded into every level of our organization, from ownership to our field crews. And it’s designed to prioritize your facility's needs first – as contracting should be.

For engineers and facility managers in demanding industries - steel, aluminum, chemical, high-heat, and corrosive environments - this cultural distinction matters. Because when your roof is under assault from constant heat, chemical exposure, metal fatigue and/or manufacturing loads, you need more than contractors. You need partners who understand your world. And that’s who we are.

Working with Large-Scale Facilities and Flexible Budgeting

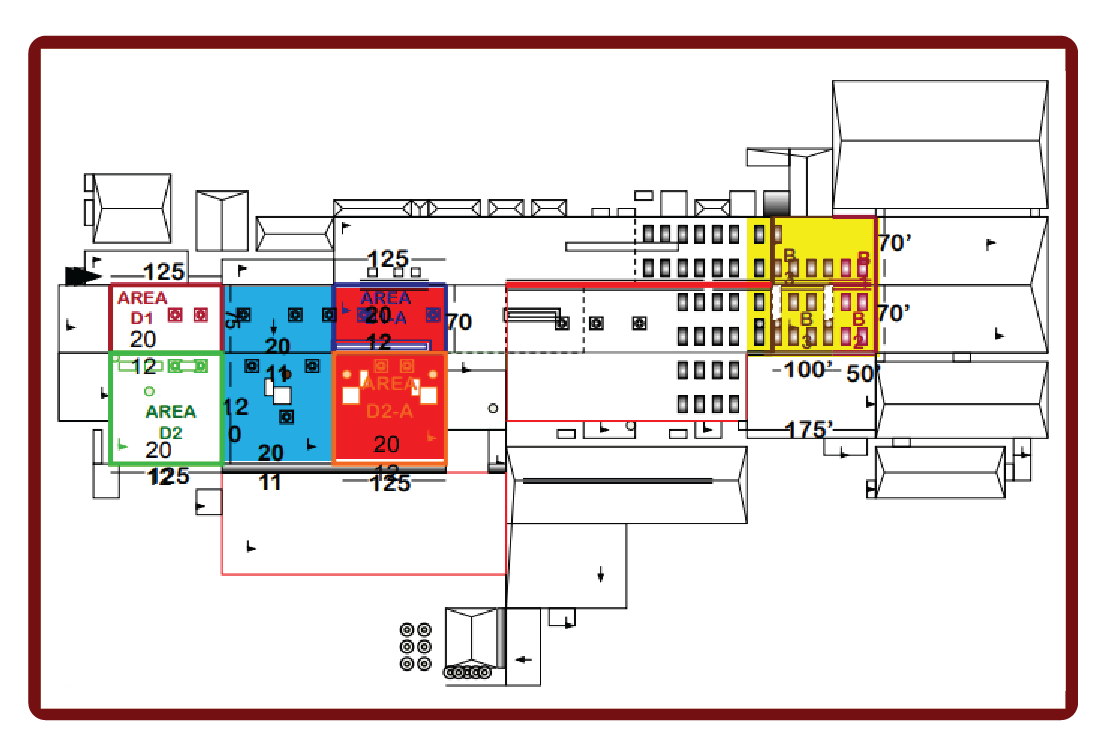

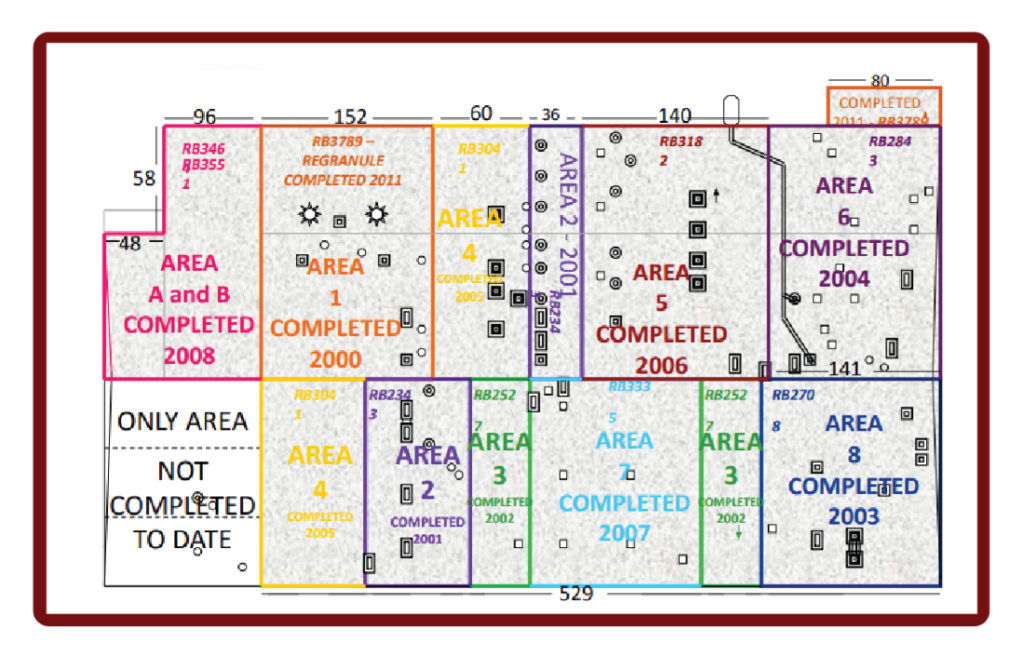

We understand that heavy-industry roofs are massive - and so are their budgets, or sometimes their budget constraints. An aluminum or steel manufacturing plant might have 3 million SQ FT of roof and CAPEX may only allow addressing the most urgent section now.

Our Top-Down Approach gives you

flexibility: we collaborate with you to parcel

out projects, focus first on the highest-priority zones, and schedule follow-up work year after year or as budgets allow.

A section-by-section restoration, rather than full replacement, can be a key route for many large

industrial metal roofs. By phasing the work, we help you align with your budget cycles, coordinate with production schedules, and maintain a consistent roofing partner and system across years - so you don't end up with multiple patchwork contractors and inconsistent systems.

Proprietary Roof System: Manufacture. Install. Warrant.

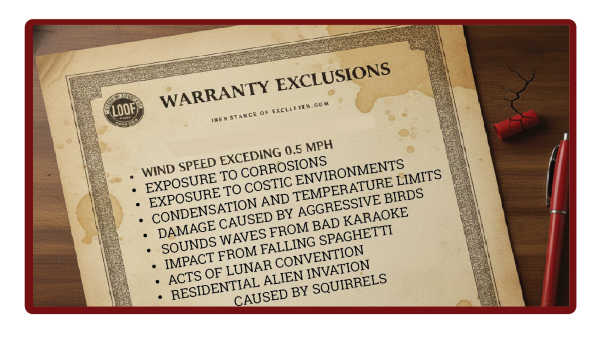

One of the hallmark features of our approach is that Thermal-Tec is the manufacturer, installer, and warrantor of our proprietary MR Multi-Ply® Roofing System. That means you have a single accountable entity for product performance, installation quality, and warranty coverage. We emphasize this to break the typical roofing warranty confusion.

In many single-ply systems you have manufacturer warranties, contractor workmanship warranties, exclusions, and fine print. With our system, you get direct accountability: full system, no-leak guarantee, no wind-uplift exclusions, full labor and material coverage for the lifetime of the warranty.

For your facility - particularly in high-stakes environments - this is critical. You're not wrestling across multiple parties when you have a leak in a volatile, corrosive environment or a roof failure when uptime is king. We own it.

No Hand-holding: We Fit Your Environment.

In aggressive industries, many general commercial roofers struggle because they require a lot of oversight or "babysitting." But for plants with strict safety protocols, tight production windows and heavy equipment, that just won't do.

Our Top-Down Approach means we don't need to be hand-held. We've built the norms of your facility into ours. From coordinating with your operations team to matching your production schedules to adhering to your safety, environmental and housekeeping rules; we integrate seamlessly. For instance, if a steel plant demands certain PPE, hot-work bans, and strict access control, our crews

arrive having already integrated into your safety stand-down, permitting and housekeeping expectations. You don't have to raise your guard - they know the terrain. This reduces stress on your staff, minimizes production disruption, and keeps the roofing work from becoming yet another "project headache." You only know we’ve been there because your roof no longer leaks, and weather permitting, space is now available for production.

40 Years of Heavy Industry Experience

When you've been restoring and reinforcing roofs in high-heat, aggressive, corrosion-prone environments for over four decades - as Thermal-Tec has - you build more than experience: you build institutional knowledge. That longevity matters when you're working in plants where:

We serve sectors like steel/aluminum manufacturing, chemical plants, plastics/rubber manufacturing, agriculture, municipalities, government facilities, and more. Because of that focus, our crews and leadership not only understand your facility roof - but your manufacturing environment.

Cultural Transference: from Ownership Down to Field Crews

A culture of safety, professionalism and heavy-industry understanding isn't just a marketing statement - it's in our DNA. Our nationally recognized safety program is a testament to that goal. Over 40 years in business with no recordable OSHA incidents and earning consecutive top-level safety awards from Associated Builders and Contractors (ABC) through the STEP safety management system. Additionally, Thermal-Tec was invited to Washington, D.C., where the company was awarded ABC’s top honor, the National Safety Excellence Award, in 2008.

This means your facility isn't dealing with a subcontractor uncertain of your protocols - it's dealing with a roofing partner whose culture is already built around high-risk, complex manufacturing sites. When you're managing a melt shop or pickling operation, you don't want to spend time babysitting your roofing contractor to make sure they follow site rules. With Thermal-Tec, that expectation is flipped: we mirror your culture and safety norms - and in many cases exceed them.

We Make Roofing Projects a Non-Event for You

Finally, our Top-Down Approach ties into the "non- event" philosophy: when you're managing a steel plant, an aluminum rolling mill or a chemical processing facility, you don't want roofing to become an operational disruption, a headache, or a production risk. With Thermal-Tec, you’ll barely notice we were there - except the roof is secured, the site is cleaner, & your facility’s needs are met. We handle our own site logistics (porta-johns, staging, housekeeping), coordinate with your staff, leave the job cleaner than when we arrived, and treat your facility like we're part of your team. Finally, all our products are American-made and 100% renewable, aligning with sustainable goals your facility may have in reuse, materials, energy or footprint reduction.

In short: you're not just buying a roof. You're buying a roofing partner that treats your operation like our operation - and whose cultural standards, safety, product accountability and service ethic are built accordingly.

Conclusion

For engineers and facility managers in aggressive manufacturing and industrial settings, the difference between one roofing contractor and another is massive. Traditional commercial roofing firms may have generalist capabilities - but when your roof lives in an environment of molten metal, corrosive chemicals, thermal shock and minimal downtime, you need more than a one-size-fits-all approach.

With Thermal-Tec Roofing's Top-Down Approach, you get a cultural partner: 40+ years' experience in heavy industry, a safety-first mindset embedded throughout the organization, no need for oversight or hand-holding, a flexible work-phasing model for large-scale roofs, a single-source proprietary system with full accountability, and a commitment to making the project a non-event for you.

If you're managing a facility where roofing failure is not merely an inconvenience but a significant operational risk, let's talk. With Thermal-Tec you're not just contracting a roof - you're planning for your success with a company that understands your world from the top down.